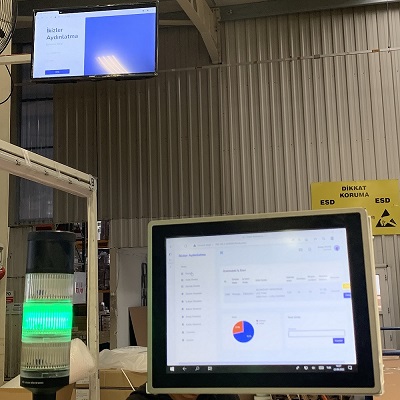

I-Andon (Integrated Andon)

Anlık Üretim Hattı İzleme Sistemi

Andon, özellikle Japon üretim yöntemlerini izleyen Otomotiv endüstrisinde kullanılan hata önleme sistemidir. Sistemin özü, personelin önündeki düğmeler yardımıyla sıra dışı durumu yetkililere bildirebilmesi esasına dayanır.

Yapılan bildirim;

1 -Genellikle LED-Matrix panolarda kullanıcı kodu-hata kodu şeklinde görünür.

2 -Günümüzde LCD ve Plazma televizyonların ucuzlaması ile, led matrix panolar yerine bu tür görüntü arabirimleri daha sık kullanılmkatadır.

3 -Sesli uyarı sistemi ile birlikte anons edilir.

4 -Bilgisayar yazılımı yardımıyla raporlanır.

Andon Panolarda, üretim hattının verimi, çalışma-durma süresi, üretim adedi gibi hatta ilişkin veriler de yer alabilir.

Örneğin, üretim operatörü hat durmuşsa bakımcı çağırmak, malzemesi bitmişse kanban çağırmak, üretimi yetiştiremiyorsa hat liderini çağırmak ve benzeri sebeplerle bir butona basar, hat başında bulunan bir LCD ekran yada led tabela üzerinde olay türü görüntülenir, bunula birlikte arka planda ilgili olayın süresi işlemeye başlar ve sonuç olarak sorunun türü, başladığı saati, süresi, müdahale sorumlusunun olay yerine varış süresi vb.. Veriler bilgisayar ortamında kayıt altına alınır. Daha sonrasında bu veriler analiz edilerek kronik sorunların çözülmesinde veya verimliliğin arttırılması işlerinde kullanılır.

Andon Panoları, bilgilendirme, uyarma ya da yönlendirme amaçlı da kullanılabilir (Afiyet Olsun, Hoş geldiniz, İş Emniyeti Uyarıları, Doğum günü kutlamaları vs.)